This post was originally published on Autocar

New Gen6 EV architecture includes slimmer batteries, more efficient motors and clever tech

New electric powertrain technology will allow the BMW Group to launch electric cars at a cheaper price while offering more range and better efficiency than today’s cars, the firm has claimed.

The Munich company has been working on an entirely new electric vehicle architecture, which will start to be rolled out with its forthcoming line of Neue Klasse models. Now labelled ‘Gen6’, the platform will first be used for the next BMW iX3, which will be unveiled in September and was previewed with the Vision Neue Klasse SUV concept.

The 800V platform is claimed by BMW to be a “quantum leap forward” in terms of technology compared with today’s offerings.

“Neue Klasse is not just a new car: it is a new technology,” said BMW Group purchasing and supply board member Joachim Post. The scalable platform will eventually be used by all BMW, Mini and Rolls-Royce EVs from their respective next generations.

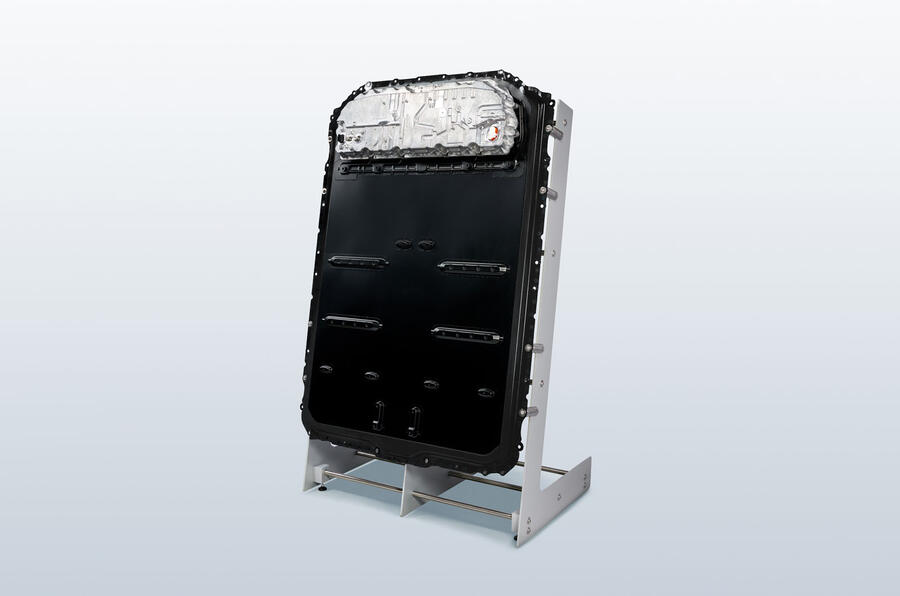

It is centred around a new nickel-manganese-cobalt (NMC) battery that uses cylindrical cells that are 20% denser and easier to package than modules (made up of square cells) found in today’s ‘Gen5’ lithium-iron packs.

The headline figures are that these new batteries increase range by 30%, efficiency by 20% and charging speeds by 30% (with bi-direction capabilities) and they reduce production costs by up to 50% compared with today’s packs. BMW has yet to disclose a capacity for the batteries that will be fitted.

These reduced costs – achieved by most of the development and assembly now being done in-house – will be passed onto buyers, said Post, instead of being swallowed as extra profit. “It is important to be competitive in the market from the price range in terms of reachability for the customers,” he said, adding that this will allow the firm to push for price parity between ICE cars and EVs.

To give an idea of the technology’s advancement, that range boost applied to the recently refreshed BMW iX – which in xDrive 60 form offers the most miles per charge in the brand’s stable – would increase its maximum range by 129 miles to 555 miles, with the ability to also add 186 miles in as little as 10 minutes.

Key to the technological advancements are the new cylindrical cells. They are built in-house in two sizes: either 95mm or 120mm tall and 46mm wide. In both instances, they are easy to package because they do not require modules to fit them together like today, said BMW. As such, they can be attached directly to the pack (called cell-to-pack) which not only saves money because fewer parts are used, but also reduces the weight and size of the batteries, allowing for slimmer batteries.

Key to the technological advancements are the new cylindrical cells. They are built in-house in two sizes: either 95mm or 120mm tall and 46mm wide. In both instances, they are easy to package because they do not require modules to fit them together like today, said BMW. As such, they can be attached directly to the pack (called cell-to-pack) which not only saves money because fewer parts are used, but also reduces the weight and size of the batteries, allowing for slimmer batteries.

As part of a “clean sheet way of thinking”, these packs are then bolted directly onto the bottom of the chassis and used as the base of the car. Today’s packs, for example, are fitted under the floor of the car, rather than forming the floor. This new technique, BMW said, increases the chassis’s structural integrity, optimises car integration, saves money on parts, reduces weight and maximises interior space.

What’s more, it means no additional battery housings are required. Coupled with the new sleek pack, this allows for sleeker, flatter and more aerodynamic car designs, potentially eliminating one of the major design hallmarks of today’s high-sided EVs.

To maximise interior space within this set-up and keep the cars’ heights as low as possible, BMW will unusually bolt the front seats directly to the pack, with the batteries’ energy master (which manages energy output and thermal levels) positioned below the rear seats.

New and updated motors are similarly important to the Gen6’s advancements. The core drivetrain is the electrically excited synchronous motor (EESM), introduced with the first-generation iX3 in 2018. It has, until now, been the only motor option offered on a BMW Group EV. This has now been heavily enhanced with an adapted inverter design, new water/oil cooling system, fettled weight and the single-speed gearbox integrated into its outer casing.

It is offered in four variants that range from 270bhp to 400bhp and is exclusively attached to the rear axle, where up to two can be fitted – both, BMW suggests, with independent gearboxes. It weighs 120kg.

New with the Gen6 platform is a small asynchronous motor (ASM) motor. Weighing just 70kg, it is offered with either 161bhp or 241bhp. It is fitted exclusively to the front axle, where – like the EESM – two can be used. This means BMW can now offer tri- and quad-motor configurations alongside the single- and dual-motor set-ups that are currently the only choices in today’s cars. The motors have been configured for use in all models from entry-level cars to top-rung M cars. BMW’s M performance division has been involved in the motor development process to enable this, BMW said.

A key brief for the new motors was efficiency. When they are combined in a dual-motor set-up, the number of miles that are lost through inefficiency is reduced by 40% compared with two last-generation EESMs. What’s more they are 20% cheaper to make and weigh 10% less. “The motors are an important contributor to the Gen6 powertrain,” said BMW.

One limiting factor of the new platform is that because the ASM does not house a gearbox, it cannot be fitted on its own, meaning future BMW Group cars, such as the iX1 and Mini models, are unlikely to be offered with a single-motor, front-wheel-drive set-up. One reason for this decision is because a rear-wheel-drive set-up is “better for dynamics”, BMW engineers told Autocar.

These motors, like the batteries, are developed and built in-house at five factories across four continents. With as many of the required production materials as possible collected within the markets in which they are built, this “ensures efficiency and enhances robustness against natural or political headwinds in the future,” said Post.