This post was originally published on Autocar

MG sibling brand IM’s L6 saloon can be had with a range-boosting semi-solid-state battery

Lighter battery tech is finally edging closer towards production after years of delays

Solid-state batteries have long been touted as the technological breakthrough that electric car makers are striving to bring to market. Finally, it looks like 2025 could mark a crucial step on the technology’s path to becoming ready for production.

These next-generation batteries are regarded as a holy grail for EVs because they offer greater capacity and more range than similar-sized lithium ion packs used today.

Those batteries are composed of an anode and a cathode at opposite ends of the cell, with a physical ‘separator’ preventing them from touching, and a gel-like liquid in the middle.

In a solid-state battery, the make-up is simplified. The liquid is replaced by a solid block, which is lighter than its counterpart and can carry more energy within the same capacity.

The solid element is also less reactive than the liquid, so it’s much less likely to ignite if punctured or heated. This means fewer ‘redundant’ safety systems are required.

The removal of a liquid element is also expected to mean the end of range drop-offs caused by high or low temperatures and the introduction of higher charging speeds.

Solid state is important to car makers because it enables more flexibility. For example, smaller and lighter EVs can be launched with comparable electric ranges to today’s models, while larger vehicles will be able to offer a much longer range from similar-sized packs.

The technology is already being tested around the globe, although it is still a few years from widespread adoption. In China, which is one market at the forefront of the technology, SAIC-owned IM Motors currently offers its L6 saloon with a semi-solid-state battery – a halfway house to a full-solid-state battery that uses a more viscous, gel-like electrolyte than the liquid in a lithium ion cell.

This pack allows an extra 33kWh of battery capacity to be crammed into the same space as an equivalent lithium ion pack. That equates to a 28% improvement in the car’s range to a total of 621 miles, according to Chinese homologation testing.

It’s not just IM Motors, either. Rival Nio launched a semi-solid pack for its ET7 saloon earlier this year, which offers more than 650 miles of range per charge.

But what about the brands you can actually buy a car from in the UK? We list their latest efforts here:

Stellantis

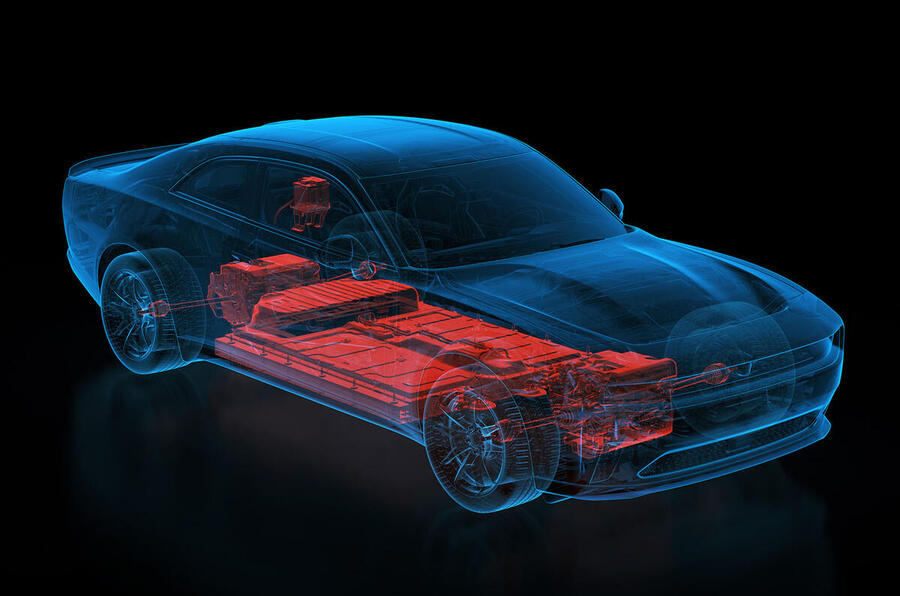

The huge multi-brand car maker will begin road testing semi-solid packs made by start-up Factorial in 2026, using a fleet of modified Dodge Charger Daytonas.

Stellantis has said it will prioritise its biggest cars from the likes of Alfa Romeo, Jeep and Maserati, based on the STLA Large platform, for the cells.

Honda

Just weeks ago, the firm opened a pilot production line for full-solid-state batteries at its research and development base in Tochigi, Japan. It will use the line to test a variety of different materials and manufacturing processes, such as “roll-pressing” electrolyte layers together to speed up production and improve output. Production testing will begin in January and the cells are scheduled for use in Honda’s hybrid and electric cars during the latter half of this decade.

Toyota

Last year, Toyota claimed to have made a “technological breakthrough” with the electrolyte’s durability – it being prone to cracking under high forces

The firm is currently working to develop a mass-production method for the cells and is eyeing a 2027 or 2028 launch. They’re claimed to yield a range of over 900 miles, and a 10-80% recharge in less than 10 minutes.

Nissan

The Japanese brand has been vocal in its ambition to launch a car with a full-solid-state battery in 2028.

This could well be the next-generation GT-R supercar – but whichever form it takes, it will have been designed to make the most of the technology.

“When you commit to something like solid state, you have to change the whole mechanism and architecture of the vehicle,” said David Moss, the company’s senior vice-president for research and development in Europe. A pilot production plant is scheduled to open next year and engineering work on the cells is expected to be finished in 2026.

BMW

BMW received pilot cells from American company Solid Power last year but shortly afterwards was reported to have said that we’re unlikely to see them in a road car before 2030. BMW M CEO Frank van Meel has previously tipped them to be key in creating lightweight electric performance cars.

Mercedes-Benz

Merc’s tech chief, Markus Schäfer, has questioned whether solid-state batteries are needed, despite the firm’s tie-up with battery maker Factorial. Earlier this year, he said they “may not be necessary”, owing to the progress made with lithium ion cells over the past few years. The brand previously said it wanted solid-state packs in its mainstream cars by 2030.

Volkswagen Group

The world’s second-biggest car maker (after Toyota) is working to upscale the technology developed by American start-up Quantumscape, with a licence agreement to produce up to 80GWh of solidstate cells (or a million cars’ worth) annually.

There’s no timeline yet but, given the scale, it’s possible that a solid-state battery could be reserved as a flagship technology for the next Golf. That car is due in 2028, which would align VW with the plans of various other manufacturers.